Moulding

Europlast deals exclusively with plastic injection moulding on horizontal and vertical moulding machines.

The produced items are intended for different sectors, ranging from the automotive sector to the home-goods sector and from sports article components to hobbies.

Each item has its own characteristics and must accordingly be produced with a specific material. Below is a brief list of the main polymers used in moulding.

PS (polystyrene), ABS (styrene copolymers), PC/ABS (blend), PC (polycarbonate), PMMA (methacrylate), IXEF (polyarylamide), PA (nylon), PBT (polybutylene terephthalate) PE LD (low density polyethylene), PE HD (high density polyethylene), PP (polypropylene), POM (acetal), PU (polyurethane), SBS (styrene butadiene styrene), SEBS (styrene ethylene butylene styrene), TPU (thermoplastic polyurethane).

Injection moulding

Injection moulding is an industrial process in which a plastic material is melted and plasticised, then injected at high pressure and velocity inside the mould where it takes shape while cooling down. After cooling, the mould is opened to extract the piece and one proceeds with the next moulding.

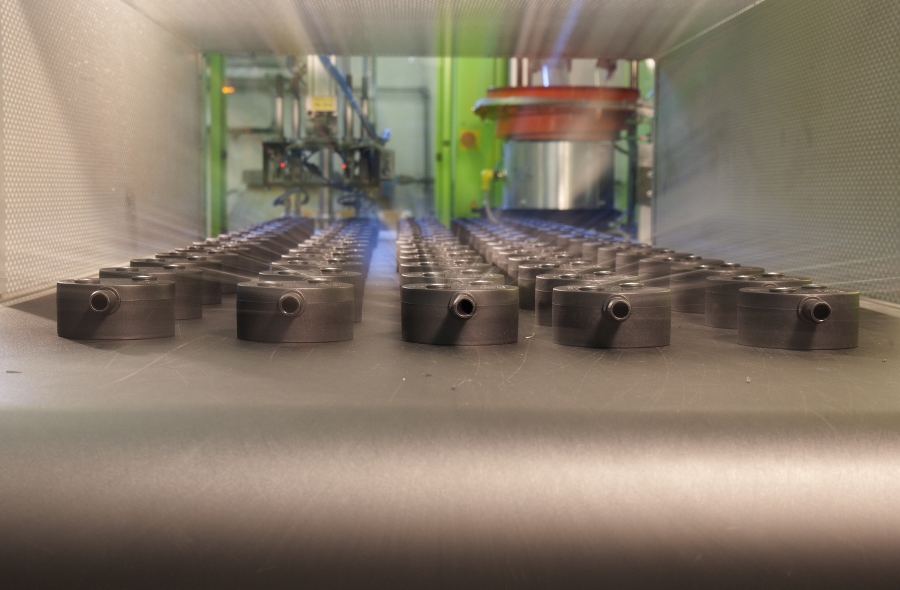

Insert moulding

In addition to the classic injection moulding, Europlast is able to carry out insert moulding or over moulding of metal or plastic inserts. This is achieved through vertical moulding machines with rotary table.

Bi-material moulding

Europlast is equipped with moulding machines for bi-material moulding, which allow for the injection of two materials that differ in type and/or colour.

IML

Europlast is able to do IML (In-Mould Labelling), which involves inserting a highly aesthetic label inside the mould prior to the injecting of the plastic material. The label is inseparable from the moulded item, guaranteeing, in addition to a better aesthetic result, also a high resistance to abrasion, UV rays and ageing in general.